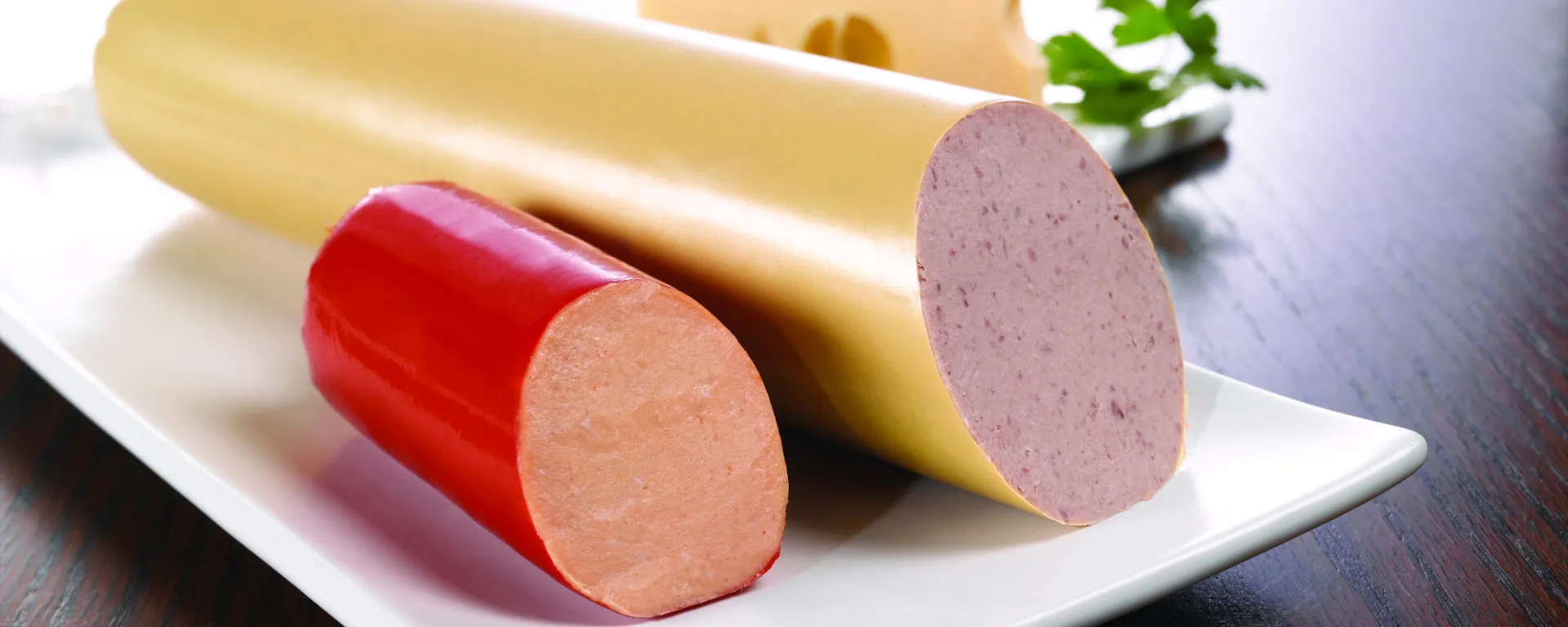

Plastic sausage casing

Nova casing

Nova is a wide group of engineered plastic casing products extruded from a variety of raw materials combined to develop unique performance properties. Ranging from one to multi-layers, each raw material is melted at an individual extruder to form a tubing. Once formed, the seamless tub ular film of many Nova products may be stretched or oriented through a bubble process to create specific mechanical and physical properties. After initial cooling the casing is stabilized through a process called annealing to provide increased durability and structural integrity. The specific manufacturing process is designed to produce a Nova product with advanced performance features, creating one of the most reliable and broadest array of plastic casing solutions in the world today.

Contact your ViskoTeepak sales representative for more information.

Adding Value With Optimized

Structures

Nova casings are manufactured with one to many layers of unique food grade plastic film resins, designed to provide optimized performance characteristics for the product application. At the same time the Nova material is manufactured, specialized characteristics are imparted to provide features such as flexibility for easy and stable size control and filling, as well as shrink and a special product contact layer to improve product yield along with ease of casing removal. These product attributes bring maximum value in the particular application.

Using Nova plastic casings

Nova casings are often filled directly out of the case or may be pre-soaked in water. Some customers achieve better performance or find it more suitable for stuffing with pre-soaking while others don't. Soaking will make certain Nova casing more flexible which allows to stuff more resulting in larger diameter products. For us to provide the most productive solution, it is crucial to understand well the customer's process and requirements.

Tailor-Made Products

ViskoTeepak casings have a multilayer structure design that can be tailor-made to fit any application or production process through the combination of different materials in each layer for the required properties. A single layer of material that alone has all the required performance properties is extremely rare. Co-extrusion allows us to combine, in one casing, the good properties of various raw materials such as mechanical strength, oxygen and water-vapor barrier for increased shelf life and zero weight loss, lower water-vapor permeability for reduced weight loss during processing and storage, etc. Moreover, each casing can be adapted to suit the customer's unique processing conditions.