History

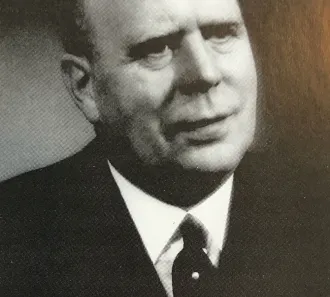

The ViskoTeepak story began in 1952 with Gunnar Eriksson enjoying a smorgasbord on a ferry between the Åland Islands and Stockholm. On that trip, Mr. Eriksson noticed on his plate a piece of sausage in an artificial casing. Einar Söderman, Mr. Eriksson’s friend who was also on the trip, had been working with a casing producer in Sweden and knew that what they were looking at was cellophane casing made from cellulose. Gunnar Eriksson became so interested that he took a piece of the casing with him to a laboratory in Helsinki. Thus the story of the greatest casing company began.

More Than 60 Years of History

To make a long story short, Gunnar Eriksson was able to raise money to start the Visko Company, and Olov Barck was successful in his analysis of the casing. The Visko casing company was established in 1952, and production was planned to begin in an old butter factory in Hanko, which had been empty since the war.

On January 8, 1953, it was declared in a local Hanko newspaper that the Visko casing company would commence production during the summer with 30 employees, with Gunnar Eriksson as president and Olov Barck as the local manager and technical leader. Production in the plant increased rapidly, and by 1956, it was moved to a newly built facility at the same location as the current plant, just outside the city of Hanko.

From its founding until 1962, all casing produced was of cellophane. In the early years, there were many innovations and changes made to the original process, and many issues had to be resolved before Visko was able to commence the commercial manufacture and sale of fibrous casings in 1962. It didn’t take long to see that fibrous casings were the future, and by the spring of 1965 the plant was expanded to 27,000 square meters.

1950

Gunnar Eriksson was enjoying a famous Scandinavian smorgasbord on a ferry boat in between Finland and the Åland Islands. While enjoying a tasteful sausage, he noticed the casing was made artificially which caught his interest. He got so curious he put a piece of the casing into his pocket and had it analyzed in a laboratory.

1952

Gunnar became convinced artificial casing was the future. He wanted to take part in this industry and raised some money to start the Visko Company in Hanko, Finland. Visko started to manufacture cellophane casings with just 30 employees.

1962

Visko started to manufacture fibrous casings.

1965

The converting center in Delfzijl, Netherlands opened.

1975

The cellulose and fibrous manufacturing plant in Lommel, Belgium was established.

1994

The cellulose converting center in the Czech Republic opened.

1995

Production of Nova plastic casing started.

2007

The current owners of ViskoTeepak believed in the future of the industry and were willing to create a world-leading seller, producer, and supplier of artificial casings. By merging Visko and Teepak into one, a new era began!

2011

The sales and logistics center in Hamburg, Germany was acquired.

2014

The fibrous converting center in Kenosha, USA merged with ViskoTeepak.

2020

The fibrous converting center in Poznan, Poland was acquired.

Today

ViskoTeepak is #MakingFoodMoreAccessible by tailor-making productive solutions in close collaboration with the global food chain.

A further look into history

ViskoTeepak at Delfzijl, Lommel and Slavkov

During the 1960s, the importance of Europe as a casing market became clear to the whole industry. Teepak, which was only operating from the U.S. at that point, decided to open its first service center in Europe. In 1965, a conversion facility (now known as ViskoTeepak Delfzijl) was opened in the Netherlands. To meet the increasing demand and enable shorter delivery times, Teepak decided to open a new production facility in Europe in 1975, the location of which was in Lommel, Belgium. In Hanko, only fibrous casing is manufactured, while in Lommel Wienie-Pak cellulose casing is also produced. The company expanded even further in 1994 by opening the Wienie-Pak shirring facility in Slavkov. This same operation and production was moved to Brno in 2012.

Product Innovations

Over the years, ViskoTeepak has placed great emphasis on product development in order to meet the demands of the market. The Visko Light fibrous casing, for example, has been a big seller since the 1990s. In 2001, the world’s biggest fibrous casing--called Jumbo--was manufactured. In the 1970’s, the first fully automatic shirring machine was installed at the Delfzijl facility, and Wienie-Pak cellulose casing has been a major success from the Lommel plant. These are just a few of the many success stories.

Plastic Casings

Plastic casings became dominant in the market at the start of the 1990s, and consequently Nova Casing was established in Godby, Finland, in 1995. The production of plastic casings was moved to Nuevo Laredo, Mexico, in 2004, and it remains fully operational today.

Merger to Create Today’s ViskoTeepak

The ViskoTeepak company became a reality in 2007 after the merger of Visko and Teepak. The company now consists of the former Visko and Teepak’s European facilities and Nova Casing. ViskoTeepak is now one of the world’s largest sausage casing manufacturer, with four plants in Europe, one in the USA and one in Central America. The company today has sales offices in Moscow, Tokyo, Shanghai, Mexico City and the head office in Mariehamn. In total, ViskoTeepak employs around 1,100 people.